General Purpose Probes

54-400-019 with a 90° conical diamond stylus, .0004" (10µm) radius per ANSI-B46, ISO, and MIL specs.54-400-026 with a 90° conical diamond stylus, .0002" (5µm) radius per DIN-4768 and certain ISO specs. |

|

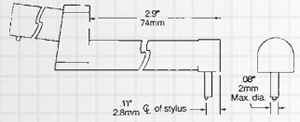

Parallel Chisel Probe (Optional)

54-420-002 with a 90° sapphire chisel, .0004" (10µm) radius. Gages sharp edges or small OD's where probe is perpendicular (in 90° or 270° position) to axis of traverse. Also for OD's smaller that .25" (6.35mm) staged on 54-400-421 Vee fixture. |

|

Traverse Chisel Probe (Optional)

54-420-001 with a 90° sapphire chisel, .0004" (10µm) radius. Gages sharp edges or small OD's where probe is aligned with (in 180° or closed position) axis of traverse. |

|

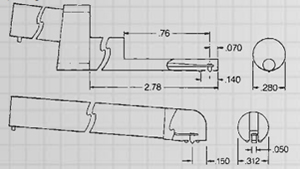

Groove Bottom Probe (Optional)

54-420-028 with a 90° conical diamond stylus, .0004" (10µm)

radius. Gages grooves, recesses and holes to depths of .25"

(6.35mm). Also used for short lands and shoulders. (Groove Bottom

Probes can only be used in the 180° position with the Pocket Surf,

supported in the height stand or a similar fixture.)

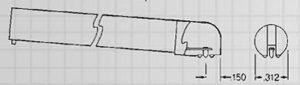

Small Bore Probes (Optional)

54-420-021 with a 90° conical diamond stylus, .0004" (10µm) radius.

54-420-027 with a 90° conical diamond stylus, .0002" (5µm) radius.

Gages small bores (1/8 (3.2mm) min. I.D.) up to a depth of 3/4" (19mm).

(Small Bore Probes can only be used in the 180° position with the Pocket Surf,

supported in the height stand or a similar fixture.)

Common profilometer Errors and Problems:

Profilometers are complex machines capable of making extremely accurate measurements if working correctly and used properly. Considering the environment they are used in, and with multiple operators, that eventually these gages fail and need repair. |

| |

- Worn Buttons

- Dropped, lcd, Driver Not Moving

- Repair, Rebuild, Sticking, Not Repeating, Will Not Calibrate

- Battery Icon, Battery Low Indicator,

- Battery Indicator, Replacement Battery,

- Dead Battery

- 888 -

- Bat Err

- Bat

- Err

- Det Err

- Will Not Move, Does Nothing, No Response

- Alarm

- Not Reading Correctly

|

- No Display

- Faulty Detector

- Faulty Encoder

- Batteries Won’t Charge

- Replacement Part Shortage

- Incorrect Readings

- Faded Display

- Probe Won’t Move Up

- Probe Won’t Move Down

- Won’t Repeat

- No Repeatability

- Not Reading

- Will Not Repeat (No Repeatability)

- Broken Tip

- Display Error

- Buttons Won’t Work

|

| |

|

While some of these problems may be relatively minor, it's always best to have a professional service these products. There are very few repair shops that can competently complete this sort of work as this is a piece of precision equipment that should be repaired by someone specializing in the field.

These gages require a number of specialized tools to disassemble and repair as well as an anti static environment. Trust your valuable tools to Bryco Industrial Service for quality, professional service. |

|